3:19

3:19

Xin chờ trong giây lát...

HOW IS SOLAR BATTERY CREATED?

Trina Solar Group specializes in researching, manufacturing solar panels and investing in renewable energy solutions leading in the world, has over 50 branches globally, products are present in more than 150 countries. When choosing Thai Nguyen as an investment destination, Trina Solar always receives the best companionship, support of the province's favorable conditions within the legal framework to accelerate the implementation of the Trina Solar Energy Development Plant project at Yen Binh Industrial Park. The project has a total investment of 203 million USD, producing photovoltaic cells and solar modules, with a production scale of 594,870,000 products/year.

In particular, photovoltaic cells, also known as solar cells (PV), are semiconductor elements that work to generate electricity directly from sunlight. These solar generating elements are connected to the circuit, are arranged neatly and uniformly in an aluminum frame, which is a complete solar panel according to the KW number set by the manufacturer.

1. PRE-WASHING

Pre-washing is the stage of cleaning the silicon sheet before putting it into the following stages, all dirt on the surface of the silicon sheet will be completely removed.

2. PLUG BATTERY DIFFUSER

Through the battery diffusion process, the pure silicon is doped with phosphorus to create a semiconductor electron capable of conducting electricity.

3. LASER

Laser is a technique that uses lasers to increase local electrical conductivity, which is considered promising because of its many advantages, including usability at room temperature, and the ease of control over a few parameters. In addition, this is also a low-cost and industrial-friendly way to increase the efficiency of solar cells.

4. FRONT OXY

Front oxygen is a method that allows the front face of silicon to react with gases containing oxygen or nitrogen to form silicon dioxide.

5. POLISHING

Polishing is the stage where the silicones are washed and polished for the next stage.

6. BACKSIDE OXY

Backside oxygen is a method that allows the silicon backing to react with gases containing oxygen or nitrogen to form silicon dioxide.

7. ALUMINUM PLATING

Aluminum plating is coating a thin layer of aluminum on the surface of solar cells to reduce light reflection and increase light transmission.

8. PLUG BATTERY

Through the battery plugging stage to measure the volt-ampere characteristic curve of the solar cell. The main parameters to be measured are open circuit voltage, short circuit current, peak power point, optimal operating voltage, optimal operating current, conversion efficiency, etc.

9. NETWORK PRINTING

Mesh printing is the process in which metal contacts are combined with the surface of a solar cell to create a low-resistance path for electrons to flow out to the interconnecting wires between the cells.

10. INSPECTION, CLASSIFICATION

This is the process of checking for defective, broken, substandard batteries and removing them from the line.

11. PACKING

Complete panels are selected to pack 10 panels in a package and can be shipped.

Trina Solar's project is deploying production in the direction of high technology, environmentally friendly, in line with the investment attraction orientation of Thai Nguyen. At the same time, contributing to helping Thai Nguyen have the opportunity to receive technology transfer, advanced management experience, expand markets, create jobs, raise incomes for workers, transform the economic structure according to modern direction, creating a positive spillover effect to other investors.

Mr. Duong Tuan Ba – Production Manager: We have a fixed training program every month, including training on techniques, company culture and workshop issues. I have worked in this profession for ten years, I find that Vietnamese employees are very industrious, hardworking, have strong will. They are my best employees.

In particular, photovoltaic cells, also known as solar cells (PV), are semiconductor elements that work to generate electricity directly from sunlight. These solar generating elements are connected to the circuit, are arranged neatly and uniformly in an aluminum frame, which is a complete solar panel according to the KW number set by the manufacturer.

1. PRE-WASHING

Pre-washing is the stage of cleaning the silicon sheet before putting it into the following stages, all dirt on the surface of the silicon sheet will be completely removed.

2. PLUG BATTERY DIFFUSER

Through the battery diffusion process, the pure silicon is doped with phosphorus to create a semiconductor electron capable of conducting electricity.

3. LASER

Laser is a technique that uses lasers to increase local electrical conductivity, which is considered promising because of its many advantages, including usability at room temperature, and the ease of control over a few parameters. In addition, this is also a low-cost and industrial-friendly way to increase the efficiency of solar cells.

4. FRONT OXY

Front oxygen is a method that allows the front face of silicon to react with gases containing oxygen or nitrogen to form silicon dioxide.

5. POLISHING

Polishing is the stage where the silicones are washed and polished for the next stage.

6. BACKSIDE OXY

Backside oxygen is a method that allows the silicon backing to react with gases containing oxygen or nitrogen to form silicon dioxide.

7. ALUMINUM PLATING

Aluminum plating is coating a thin layer of aluminum on the surface of solar cells to reduce light reflection and increase light transmission.

8. PLUG BATTERY

Through the battery plugging stage to measure the volt-ampere characteristic curve of the solar cell. The main parameters to be measured are open circuit voltage, short circuit current, peak power point, optimal operating voltage, optimal operating current, conversion efficiency, etc.

9. NETWORK PRINTING

Mesh printing is the process in which metal contacts are combined with the surface of a solar cell to create a low-resistance path for electrons to flow out to the interconnecting wires between the cells.

10. INSPECTION, CLASSIFICATION

This is the process of checking for defective, broken, substandard batteries and removing them from the line.

11. PACKING

Complete panels are selected to pack 10 panels in a package and can be shipped.

Trina Solar's project is deploying production in the direction of high technology, environmentally friendly, in line with the investment attraction orientation of Thai Nguyen. At the same time, contributing to helping Thai Nguyen have the opportunity to receive technology transfer, advanced management experience, expand markets, create jobs, raise incomes for workers, transform the economic structure according to modern direction, creating a positive spillover effect to other investors.

Mr. Duong Tuan Ba – Production Manager: We have a fixed training program every month, including training on techniques, company culture and workshop issues. I have worked in this profession for ten years, I find that Vietnamese employees are very industrious, hardworking, have strong will. They are my best employees.

Latest Video

More Video

10:27

10:27

Thai Nguyen Corner 5/9/2023

9:55

9:55

Thai Nguyen Corner 26/8/2023

9:03

9:03

Thai Nguyen Corner 8/7/2023

3:49

3:49

ART OF BREWING TEA AND ENJOYING TEA WITH ARTISTS

3:56

3:56

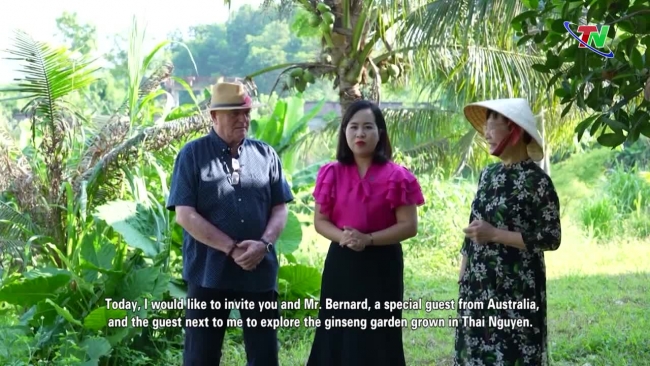

Thai Nguyen in the eyes of foreigners

9:59

9:59

Talk with Dr. Pham Thi Tuan Linh - typical young faces of Thai Nguyen province in 2021

1:07

1:07

Guidelines for issuance of vaccine passports

1:24

1:24